Smart Factories in the Era of Industry 4.0: Automation Framework, Integrating Smart Tools and Future Outlook

Exploring the digital ecosystem of Industry 4.0 and how it is reshaping modern factories through connected production, quality and maintenance practices.

Manufacturers today are under more pressure than ever—to produce faster, reduce waste, maintain quality and respond quickly to market changes. At the same time, they’re navigating rising costs, labor shortages and growing customer expectations. In this challenging environment, simply doing things the old way isn’t enough.

That’s where digital transformation comes in. Across the globe, forward-thinking companies are reimagining how factories operate by adopting smarter, more connected technologies. These changes aren’t just about efficiency—they’re reshaping how products are made, how problems are solved and how factories compete in a global economy.

This is where Industry 4.0 and smart factories come into play. They represent a new approach to manufacturing—one that relies on data, automation and real-time connectivity to drive better decisions and more agile operations.

What is Industry 4.0 and Smart Factories?

Industry 4.0, also known as the fourth industrial revolution, represents the integration of advanced digital technologies into manufacturing and industrial processes. It builds upon previous revolutions—mechanization (Industry 1.0), mass production and electricity (Industry 2.0) and automation (Industry 3.0)—by adding connectivity, intelligence and autonomy to systems.

At the heart of Industry 4.0 is the concept of the smart factory: a highly digitized and connected production facility that relies on data-driven technologies to improve efficiency, flexibility and responsiveness.

Smart factories aim to:

Monitor and Optimize production processes in real-time

Reduce downtime through effective and proactive maintenance

Improve product quality using data insights

Enhance workforce productivity with automation and augmented tools

By leveraging the power of technologies such as AI, robotics, digital twins and big data, smart factories empower manufacturers to remain competitive in a rapidly evolving market.

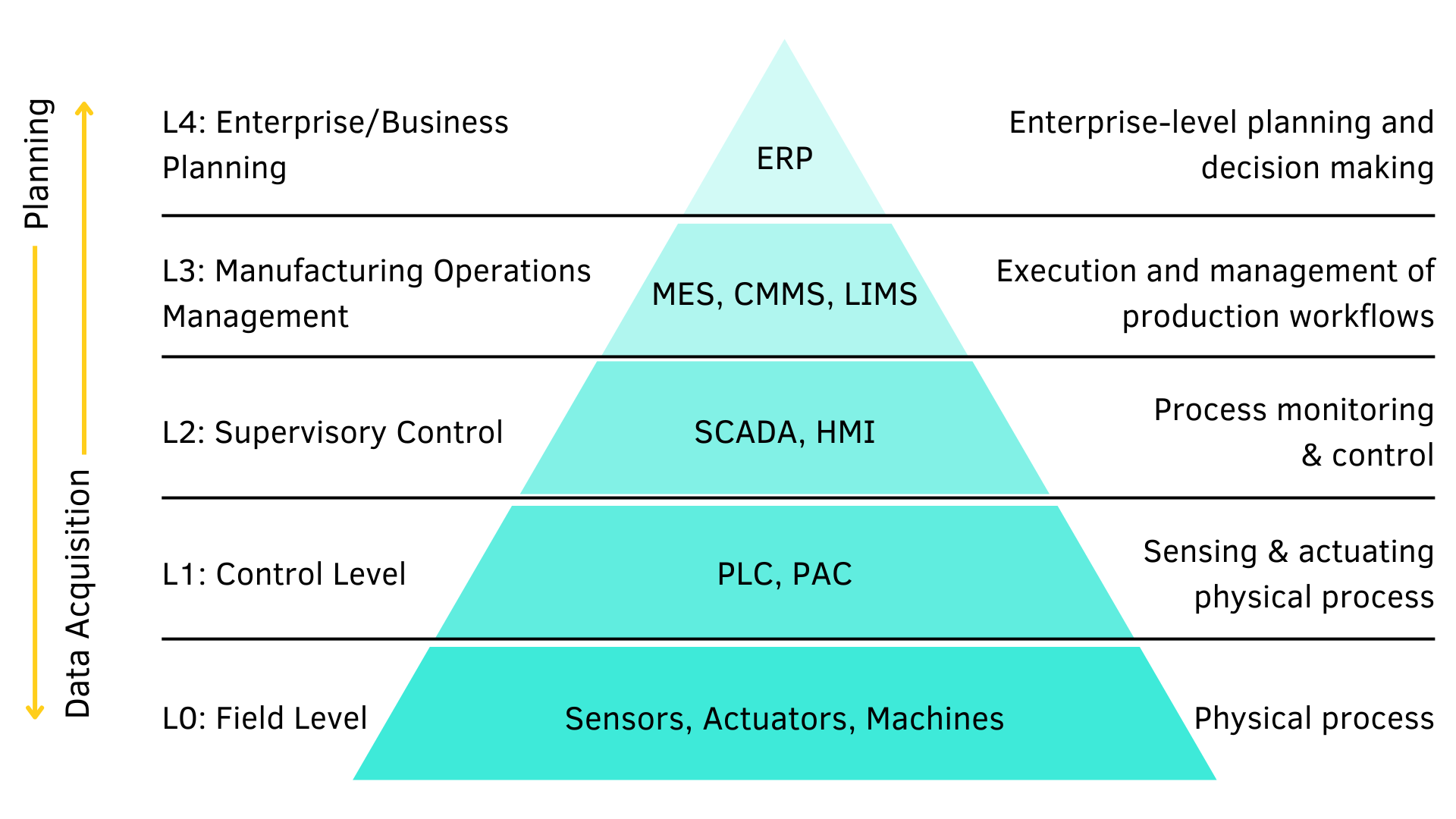

Hierarchical Automation Layers: The Framework Guiding Smart Factories

The Hierarchical Automation Layers framework, based on the ISA-95 standard, provides a structured approach to organizing Industry 4.0 technologies in smart factories. It divides the factory into functional layers – from shop-floor devices to enterprise systems – ensuring clear responsibilities, seamless data flow and scalability. As a guiding framework, it illustrates how technologies and tools can be aligned across layers to support both operational agility and strategic oversight.

Integrating Smart Factory Tools Within Automation Layers

Automation in manufacturing has evolved significantly over the past decades. Earlier systems focused on simple mechanization and basic process control, with little connectivity between machines and functions. Today, with Industry 4.0, factories are embracing smart, connected technologies that allow real-time data collection, analysis and decision-making. Tools such as AI, robotics, IoT devices, digital twins and advanced analytics are transforming how factories operate, making production faster, more flexible and more efficient.

Addition of modern day tools into the hierarchy model

L0 – Field level or Physical Process

- Industrial robots & cobots

- Autonomous Mobile Robots (AMRs) / AGVs

- Additive manufacturing (3D printing machines)

- IIoT devices (temperature, vibration, pressure sensors, machine vision cameras

Smart Conveyors/Material Handling Systems

L1 – Control Level

- Robotics controllers (motion, safety, path planning)

- Smart drives and actuators

- Local edge controllers (basic edge computing)

- AI embedded in controllers (simple anomaly detection, adaptive control)

L2 – Supervisory & Monitoring Layer

- SCADA systems connected to IoT gateways

- HMIs enhanced with real-time data visualization

- Edge computing nodes for analytics near machines

- AI at the edge (vision analytics, defect detection, anomaly monitoring)

- Cybersecurity gateways for OT networks

- Historian Databases

L3 – Manufacturing Operations Management

- MES – production scheduling, quality tracking

- Computerised maintenance management system (CMMS)

- Laboratory Information Management System (LIMS)

- AI/ML integration to CMMS

- SPC (Statistical Process Control) software

- Digital twins of production lines/factories

- AR/VR for operator support & training

L4 – Enterprise / Business Planning Systems

- ERP, PLM, SCM, CRM systems

- AI for demand forecasting, supply chain optimization, production planning

- Advanced Planning & Scheduling (APS Tools)

- Cloud platforms / data centers hosting enterprise applications

- Blockchain for traceability & compliance

- Global digital twin (enterprise-wide)

- Business Intelligence (BI)/Analytics Platforms

Related article : Maximizing Operational Efficiency through OEE.

Future Outlook of Smart Factories

Smart factories are still evolving and their future promises even greater transformation. As technologies mature and converge, factories will move beyond automation to become more intelligent, resilient and sustainable. Artificial Intelligence (AI) and Machine Learning (ML) will play a larger role, powering predictive analytics, self-optimizing processes and autonomous decision-making. Machines will not only detect problems but also recommend and implement solutions without human intervention. Digital twins — virtual replicas of entire factories — will be used more widely to simulate operations, test improvements and anticipate disruptions before they occur.

Connectivity will also expand. Edge computing will allow faster local decision-making, while 5G networks will enable real-time communication across machines, workers and systems. Cybersecurity will become a top priority as more devices and systems connect to the cloud, requiring robust defenses against potential threats. Sustainability will be another defining factor. Smart factories of the future will aim to reduce energy consumption, minimize waste and optimize resource usage, aligning with global environmental goals and customer expectations for greener products.

Perhaps most importantly, the workforce will continue to evolve. Human workers will collaborate with AI and robotics, focusing less on repetitive tasks and more on problem-solving, innovation and value-added roles.

In short, the future factory will be a dynamic ecosystem — highly connected, self-learning and environmentally responsible — setting new standards for how products are designed, produced and delivered worldwide.