End-to-End Sales and Operations Planning (S&OP)

Gain a thorough and in-depth understanding of every stage and aspect of the entire sales and operations planning process

Sales and Operations Planning (S&OP) is an integrated, cross-functional planning process that aligns sales, marketing, operations, supply chain, product development, and finance to balance supply and demand. Through a structured monthly cycle, Sales and Operations Planning (S&OP) helps organizations create a unified plan that supports both strategic and operational objectives.

By providing full visibility across the value chain, Sales and Operations Planning (S&OP) enables more accurate forecasting, improved resource allocation, and better decision-making. It ensures that demand plans are realistic, supply capabilities are optimized, and inventory levels are maintained at the right balance.

In addition, Sales and Operations Planning (S&OP) strengthens collaboration between departments, reduces uncertainty, and promotes proactive management of risks and opportunities. With consistent alignment of operational activities to financial goals, Sales and Operations Planning (S&OP) becomes a critical driver of organizational efficiency and profitability.

Ultimately, Sales and Operations Planning (S&OP) provides a single, integrated framework that harmonizes demand, supply, and financial planning to deliver sustainable growth and improved performance.

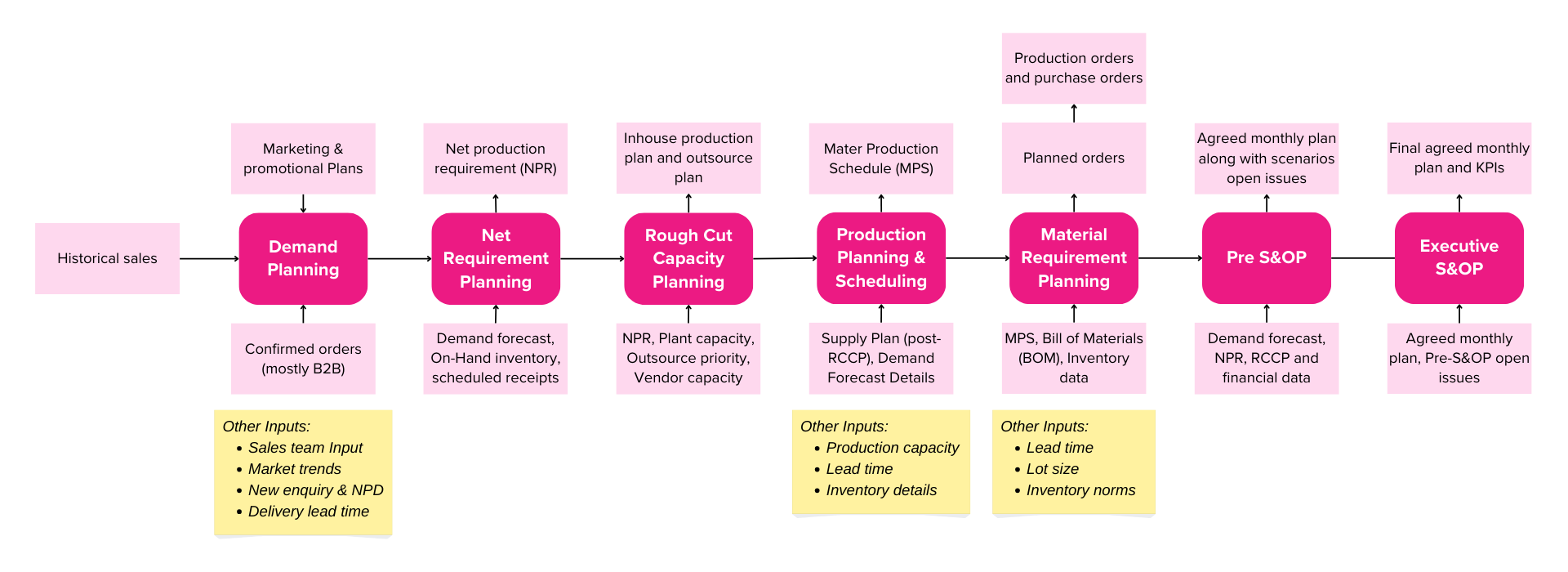

Sales and Operations Planning (S&OP) Process Flow

1. Demand Planning: Setting the Foundation

Demand Planning is the starting point of the sales and operations planning (S&OP) process where cross-functional teams including sales, marketing, product development and often finance and supply chain collaborate to forecast future demand for products.

Impact:

Establishes a realistic demand baseline, reducing the risk of overproduction (leading to excess inventory) or underproduction (causing stockouts) which sets the stage for effective supply planning.

- Historical sales data from past periods.

- Marketing and promotional plans such as upcoming campaigns or seasonal events.

- Confirmed orders from customers, typically from business-to-business (B2B) agreements.

- Market trends, input from sales team, customer feedback, new inquiries & new product development and delivery lead times

- Sales and marketing teams analyze historical sales patterns, adjust for market trends, and incorporate promotional impacts. They combine firm customer orders with projected consumer demand to create a comprehensive forecast, often broken down by time periods, customer segments, and product variants.

- A demand forecast that outlines expected sales over a planning horizon, segmented by time, customer, and product type.

2. Net Requirement Planning (NRP): Calculating What’s Needed

Net Requirement Planning (NRP) determines the actual production or procurement needed by adjusting the demand forecast for available inventory.

Impact:

Prevents overstocking by ensuring production aligns with actual requirement, minimizing excess inventory while ensuring sufficient stock to meet demand.

- Demand forecast from the Demand Planning stage.

- On-hand inventory levels in warehouses or stores.

- Scheduled receipts such as confirmed deliveries of finished goods expected to arrive.

- NRP subtracts on-hand inventory and scheduled receipts from the demand forecast to calculate the net production requirement. This ensures that only the additional units needed are planned for production or procurement.

- A demand forecast that outlines expected sales over a planning horizon, segmented by time, customer, and product type.

3. Rough Cut Capacity Planning (RCCP): Validating Feasibility

Rough Cut Capacity Planning (RCCP) assesses whether the net production requirements can be met with available production capacity, considering resource constraints.

Impact:

Ensures production plans at monthly & quarterly levels are realistic by identifying bottlenecks early and aligning with capacity constraints by adjusting plan – scaling back, spreading production, or outsourcing. Also helps secure vendor capacity early for outsourcing when needed to close capacity gaps

- Net production requirement (NPR) from Net Requirement Planning.

- Plant capacity, including machine hours, labor availability and production line constraints.

- Outsourcing criteria and vendor capacity & capability

- Logistics capacity such as warehouse storage limits or shipping constraints.

- RCCP compares the net production requirement against in-house production capacity (category/product level) over the planning horizon. If the requirement exceeds capacity then options like outsourcing, overtime, or production adjustments are evaluated to ensure feasibility.

- A capacity-feasible plan that outlines how much can be produced in-house and additional measures (e.g. outsourcing, overtime) are needed to meet the NPR.

4. Production Planning & Scheduling: Creating the Master Schedule

Production Planning & Scheduling translates the sales and operations planning (S&OP) – supply plan (post RCCP and agreed for in-house production) into a detailed production schedule, specifying what to produce and when

Impact:

Ensures production is timed to meet demand, minimizing inventory holding costs by avoiding early production and preventing stockouts by meeting delivery deadlines.

- Supply plan from RCCP.

- Demand forecast details, such as customer-specific delivery schedules, time-phased demand and product variants.

- Production capacity at granular level, including detailed resource availability (e.g., machine hours, labor shifts).

- Lead times for production processes.

- Production Planning creates a Master Production Schedule (MPS) that breaks down the supply plan into time-phased production targets (e.g., weekly or monthly). Scheduling assigns production to specific lines, shifts or facilities ensuring alignment with customer delivery deadlines and capacity constraints.

- MPS, detailing production quantities and timing over the planning horizon.

- A detailed production schedule specifying which products are produced on which lines and in which time periods.

5. Material Requirement Planning (MRP): Securing Materials

Material Requirement Planning (MRP) calculates the materials needed to support the MPS, ensuring raw materials are available for production.

Impact:

Optimizes raw material inventory by ordering only what’s needed, reducing holding costs for excess materials and ensuring production isn’t delayed due to material shortages.

- MPS from Production Planning & Scheduling.

- Bill of Materials (BOM) listing the components required for each product.

- Inventory data including on-hand raw materials and scheduled receipts of materials.

- Lead times for material procurement, lot sizes for ordering and inventory norms (e.g., safety stock levels).

- MRP uses the MPS and BOM to determine the total material requirements. It nets out on-hand inventory and scheduled receipts, then accounts for lead times and lot sizes to schedule material orders ensuring availability when production begins.

- Planned orders for materials which are later converted into purchase orders (for materials procurement) and into production orders (for in-house manufacturing)

6. Pre-S&OP: Reconciling Demand and Supply

The Pre-S&OP meeting brings together representatives from sales, operations, supply chain, and finance along with demand and supply planners to reconcile the demand and supply plans, resolve gaps and prepare recommendations for executives.

Impact:

Aligns demand and supply plans ensuring feasibility and cost-effectiveness while preparing a comprehensive plan that balances service levels with financial goals.

- Demand forecast from Demand Planning.

- Capacity constraints identified in RCCP.

- Supply plan from Production Planning & Scheduling adjusted for capacity constraints.

- Financial data including budgets, production costs, margins and profitability targets.

- Logistics constraints such as shipping costs, delivery capacity and warehouse limits.

- Last month’s performance review including metrics like on-time delivery.

- The team reviews the demand and supply plans and gaps (e.g., capacity shortfalls, material delays). They develop scenarios to address these gaps such as using overtime, outsourcing, or delaying production and evaluate each scenario’s financial and operational impacts. A recommended plan is agreed upon along with alternative scenarios for executive review.

- Agreed monthly plan

- Scenario options, presenting alternatives with their trade-offs.

- Open issues such as unresolved risks (e.g., material delays) that need executive input.

7. Executive S&OP: Final Approval and Strategic Alignment

The Executive sales and operations planning (S&OP) meeting involves senior leadership to review the Pre-S&OP recommendations, approve the final plan and set strategic goals for the next cycle.

Impact:

Ensures the plan aligns with the company’s strategic goals, provides clear direction for execution and drives continuous improvement through feedback and KPIs.

- Agreed monthly plan from Pre-S&OP.

- Scenario options, including alternative strategies and their impacts.

- Open issues requiring executive decision-making.

- Executives review the proposed plan and scenarios, assessing their alignment with strategic objectives (e.g., profitability, service levels). They approve the final plan, resolve open issues (e.g., approving additional spending to expedite materials), and set key performance indicators (KPIs) for the next cycle.

- Final agreed monthly plan ready for execution.

- KPI targets

Sales and Operations Planning (S&OP) Monthly Calendar

16th to 18th

of the month

Demand Planning

21st to 23rd

of the month

Supply Planning

25th

of the month

Pre S&OP

28th

of the month

Executive S&OP